How Does Vision Inspection System Work?

Keyur Patel

September 12, 2025

7 min

As the demand for high-quality products skyrockets daily, companies must double-check that every product meets stringent quality standards before they are sent to the market. However, with modern technologies taking over manufacturing operations already, machine vision systems will likely replace the conventional product inspection process.

Implementing the vision inspection system provides impeccable benefits such as improved quality control measures, increased productivity, reduced waste, and optimized processes in place for a reliable production process.

In this blog, we will go through vision inspection systems and their functioning.

Let’s begin this with a very basic question,

What is a Vision Inspection System?

A vision inspection system also referred to as a machine vision system is a combination of advanced technologies designed to automatically inspect and assess objects for various functionalities.

The system works by using high-resolution cameras, lights, and software to capture and analyze visual information of items on the assembly line. The products are checked to ensure that the quality of standards remains maintained.

A vision inspection system consists of hardware and software solutions that are trained to replicate human vision.

It serves as a great tool that detects defects, contaminants, misalignment, incorrect labeling, and product distortion or measurement issues at a high speed. The adoption of these systems has spread across various industries, each utilizing them for different purposes. From pharmaceuticals to food production to packaging, or the automotive industry, each one of these industries relies on vision inspection systems to keep a check on the quality of products.

These systems are trained to make decisions for the functions they are trying to assess and trigger an operation if needed. For example, if a vision inspection system is trained to check the level of water filled in the water packaging industry, it quickly identifies a bottle that is less filled than the defined quantity and throws an alert. This way, the system operator quickly receives this notification and removes the unqualified bottle from the lines.

The constant flow of information that flows through the vision inspection system improves not only the quality, but also the efficiency, sorting, and packing of items.

Shifting to the next important question,

How Does the Vision Inspection System Work?

Vision Inspection Systems are meticulously designed to collect data and communicate important information to various parts of the machines.

The optical hardware is installed with high-definition cameras that check the system environment and pass the data to auxiliary computers.

Let us discuss how the vision inspection system’s components are interlinked and how they interact with each other.

Illumination features:

To use machine vision cameras for your business, you need to have proper lighting. This often is a constraint that manufacturing areas face while working with vision inspection systems.

However, in recent times. you can install illumination features directly into the system hardware to capture images. This allows you to adjust colors and brightness according to the requirements.

Optic Lenses:

These advanced optic lenses function beyond human eye detection. The high-resolution optic lenses can detect even X-rays and infrared lighting and can be used for area scanning and line scanning.

Optic lenses capture product pictures to compare the dimensions for area scanning. However, for capturing pictures of moving products, line scanning is important. It helps in taking multiple pictures of the product passing through the manufacturing line which helps in assessing each one of them.

Sensor:

After installing the high-quality cameras, the sensor starts receiving the message. Upon receiving the signal, the sensor converts the image into data sets that can be assessed for relevant information. This drastically improves the inspection times.

Processing components:

The digital images are further received by the processing components that transfer the image processing across the systems. The hardware and the operating software receive hundreds of images at once but can process them faster than the manual way of collecting and analyzing data.

Signal Conduits:

Signal conduits help ensure a smooth flow of information between hardware and the computer. Signal Conduits further transfer these to other machines which further prompts an action from the line handler.

Operating system:

The operating system is the heart of vision inspection systems. It is from here that you can manage the entire inspection process and optimize it for the best results.

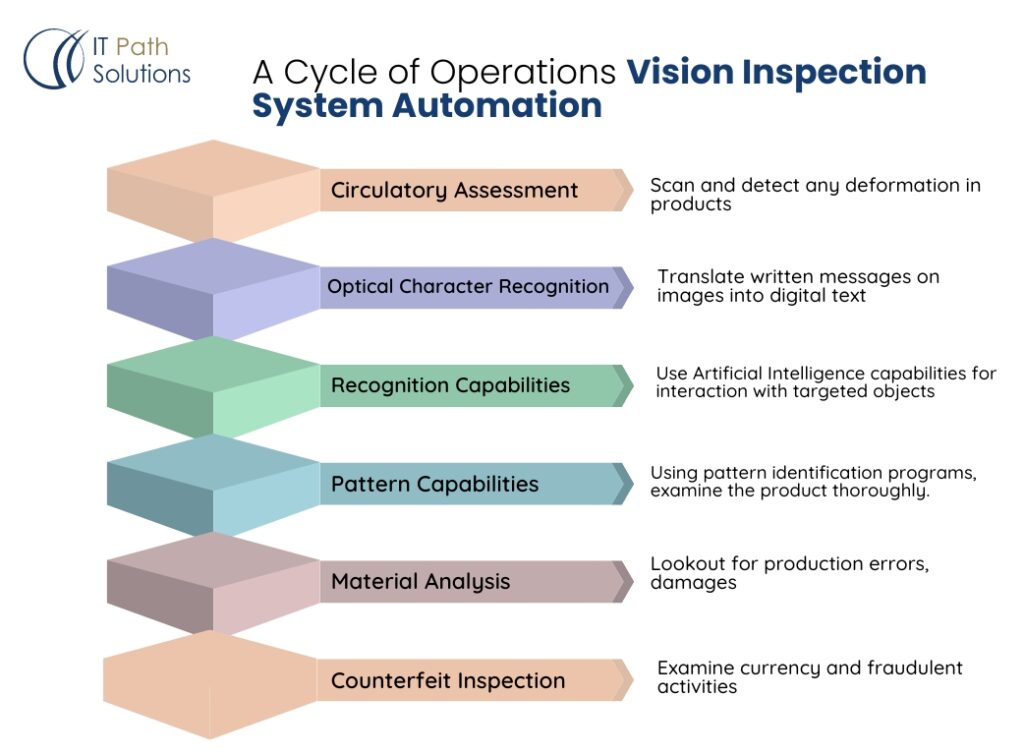

To simplify the cycle of operations, here is how you can achieve the vision inspection system automation.

Circulatory assessment: Scan and detect any deformation in products

↓

Optical Character Recognition (OCR): Translate written messages on images into digital text

↓

Recognition Capabilities: Use Artificial Intelligence capabilities for interaction with targeted objects

↓

Pattern capabilities: Using pattern identification programs, examine the product thoroughly.

↓

Material Analysis: Lookout for production errors, damages

↓

Counterfeit Inspection: Examine currency and fraudulent activities

↓

Numerical Data: Use fast computing capabilities to count products.

What is the application of the Vision Inspection System?

Vision Inspection Systems can be used in a variety of ways to improve daily functions and output quality. The following industries can benefit enormously by incorporating a vision inspection system into operations.

- Manufacturing industry;

- Pharmaceuticals;

- Packaging;

- Grocery/Supermarket;

- Food chain restaurants;

Here are some most common use cases of Vision Inspection Systems in the above-mentioned industries:

Quality Control:

From the minutest crack to big dents, a vision inspection system can detect it all. It can quickly analyze the product moving on the manufacturing line and highlight the one that doesn’t fit into the criteria. This way, the entire system gets designed in a way to release the product that matches the quality requirements.

The types of vision inspections that fall under this category are:

- Defects and Flaw detection;

- Measurement and Dimensions;

- Positioning and Alignment;

Inventory management:

Maintaining the FirstInFirstOut (FIFO) strategy manually for an extra-large inventory can be a difficult task to handle. You might need hundreds of men who can manage the tasks. But with a vision inspection system installed, you can manage the inventory with minimal human intervention.

The extra time that the staff gets once the operations are automated can be further allocated for other productive responsibilities.

The types of vision inspections that fall under this category are:

- Character Inspection and Barcode reading;

- Product verification;

- Presence and Absence of a product;

Data Analysis:

The data collected across the Vision Inspection System is centrally stored and can be accessed from any location. This facilitates easy data organization, without the need to reach out to each operating system manually.

Grading:

Automated Vision Inspection systems provide grading to materials by processing them using complex algorithms. This helps in keeping track of the quality of the materials used.

What Challenges You Might Face With The Vision Inspection System?

Vision Inspection systems are relatively new and evolving. However, they still might have a few limitations as compared to human inspections. Here are a few challenges that you might face during the implementation.

Complexity of Tasks:

Vision inspection systems might fall short in identifying complex defects or microscopic differences that are visible to the naked eye.

Cost of implementation:

If your business is scalable and requires new machinery until it is stable, then implementing a vision inspection system can be a challenging task. You will need to carefully plan things, which may require money and time investment.

How Can IT Path Solutions Help You?

IT Path Solution is an AI/ML Development company that has expertise in developing advanced vision inspection software that seamlessly integrates with your vision inspection systems. We use a range of programming languages and technologies such as Python, and .NET to develop high-speed data processing systems.

We prefer Python for its rich ecosystem and libraries such as OpenCV, and Tensorflow, which makes it ideal for real-time image processing and defect detection.

If you have any software requirements for developing a vision inspection system, get in touch with us!

Bottom Line:

Vision Inspection Systems and AI is a game-changer in the industry. The information stated above highlights how vision systems will improve efficiency and accuracy across different segments. After going through the information on how it works and what it can achieve, it is hard to deny its implementation.

If you are looking for a partner who can help you manage the software related to the use of the Vision Inspection System, please get in touch with us!

Keyur Patel

Co-Founder

Keyur Patel is the director at IT Path Solutions, where he helps businesses develop scalable applications. With his extensive experience and visionary approach, he leads the team to create futuristic solutions. Keyur Patel has exceptional leadership skills and technical expertise in Node.js, .Net, React.js, AI/ML, and PHP frameworks. His dedication to driving digital transformation makes him an invaluable asset to the company.

Get in Touch

Search

Blog Categories